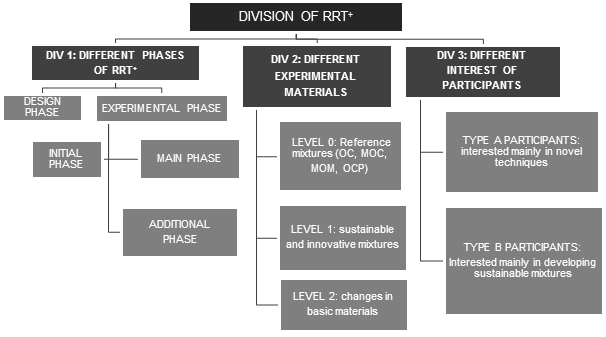

RRT+ ORGANIZATION The organization of RRT+ is divided to:

- two different phases according to main objectives of RRT (DIV1);

- three different levels according to the materials used to perform necessary experiments (DIV2);

- two different types according to the interest of the participants (DIV3)

Different phases of RRT – DIV1

According to its nature, RRT can be divided into the following two phases: i) design phase and ii) experimental phase. Design phase is aimed to prepare a detailed plan of RRT procedure, namely: (1) to define testing laboratories, (2) to define experimental materials (i.e. basic materials and mixtures), (3) to define mixing procedure and curing conditions, (4) to define testing methods and (5) to prepare detailed experimental plans for each GP1. Experimental phase can be further divided into the following two sub-phases: (1) main phase, and (2) additional phase. During the main phase, a vast majority of RRT procedure will be performed used to achieve main objectives of RRT. Additional phase will be performed on the basis of the results of main phase and also on basis of the results of the numerical benchmarking.

Different levels of RRT

According to type of experimental materials, RRT be divided into three different levels. Level 0 is the basic level of RRT which deals with two reference concrete mixes, i.e. ordinary concrete (in the following “OC”) and modified ordinary concrete (MOC) with a decreased water/cement ratio in order to emphasize the effect of the amount of available water for hydration in the mix. Both OC and MOC use the same basic materials, namely Portland cement with clinker and crushed natural aggregate, and have therefore strong environmental effect.

Level 1 is focusing on sustainable and innovative CBM compositions. The idea of this level is to propose mixes with lower environmental effect and compare their properties with basic reference mixes from level 0. These mixes are called “ECO concrete mixtures” (ECOC) and can be formed by substituting part of the constituting material with a more sustainable alternative and/or by using a different type of constituting materials. Here the highlight should be given to locally available materials and mixes originally developed by a participating laboratory. Consequently, each participating laboratory is encouraged to use its own supplementary materials.

Level 2 is the level in which participants can modify reference mixes to obtain desired variations, necessary for validation of their experimental techniques. In that case, participants can propose mixes that suit their experimental technique, but are still based on the reference mixes and use the same constituting materials (changes in w/c ratio, aggregate content, curing conditions, initial concrete temperature, etc. are some of the typical examples).

Different types of RRT

RRT can be divided into the following two categories according to the main interest of the participants included in RRT. Type A participants are interested in using advanced, non-standardized experimental techniques developed or used in their laboratories. Their aim would be to use this RRT to perform validation and benchmark of experimental technique. They can choose to use their experimental program on all three levels of RRT.

Type B participants are interested in testing their innovative, more advanced mixes with improved properties. Their aim would be to perform validation and benchmark of mixes, comparing behavior of alternative mix to basic reference mix. They can perform test using their own methods or can propose to another participant (e.g. through STSM tool) to perform test using their advanced experimental technique.